Bag Splitter

Different Tasks – Different Solutions

The special feature of the Matthiessen bag splitter / bag opener is that bags of various sizes are torn open and almost completely emptied. The recyclable materials are neither crushed nor ground – a very great advantage in subsequent sorting processes.

Different machine designs are available depending on the feed product and throughput capacity.

With our working widths of 1500mm — 1750mm — 2000mm we offer an economical solution, depending on the throughput capacity. Bunker sizes up to 60m³ are available.

Different rotor – comb – knife types allow optimal tearing and emptying results for the different input materials:

- MSW (up to 50 t/h)

- Light packaging / yellow bags (up to 20 t/h)

- Bio Waste (up to 50 t/h)

- Single Stream (up to 30 t/h)

How the Matthiessen Bag Splitter works

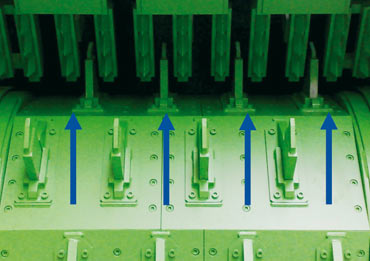

The feed hopper is loaded by means of a wheel loader or a conveyor belt provided by the customer. An integrated chain belt conveyor transports the recyclable material bags in the direction of the tear-off rotor, which picks them up and moves them in the direction of the tear-off comb (counter-holding comb). The distance between the ripping comb and the ripping tines is dimensioned in such a way that the recyclable material bags are pulled through a narrow point. The bags are torn open, but not ground. Large, bulky parts such as polystyrene parts, large packaging or even pieces of furniture are reduced to a handy size. Small parts fall out of the machine directly below the rotor onto a possible sorting belt provided by the customer.

Self-cleaning mechanisms ensure trouble-free and continuous operation.

For further information please call us,

Tel. +49 4824 309 57

or write an e-mail to

info@matthiessen-technik.de